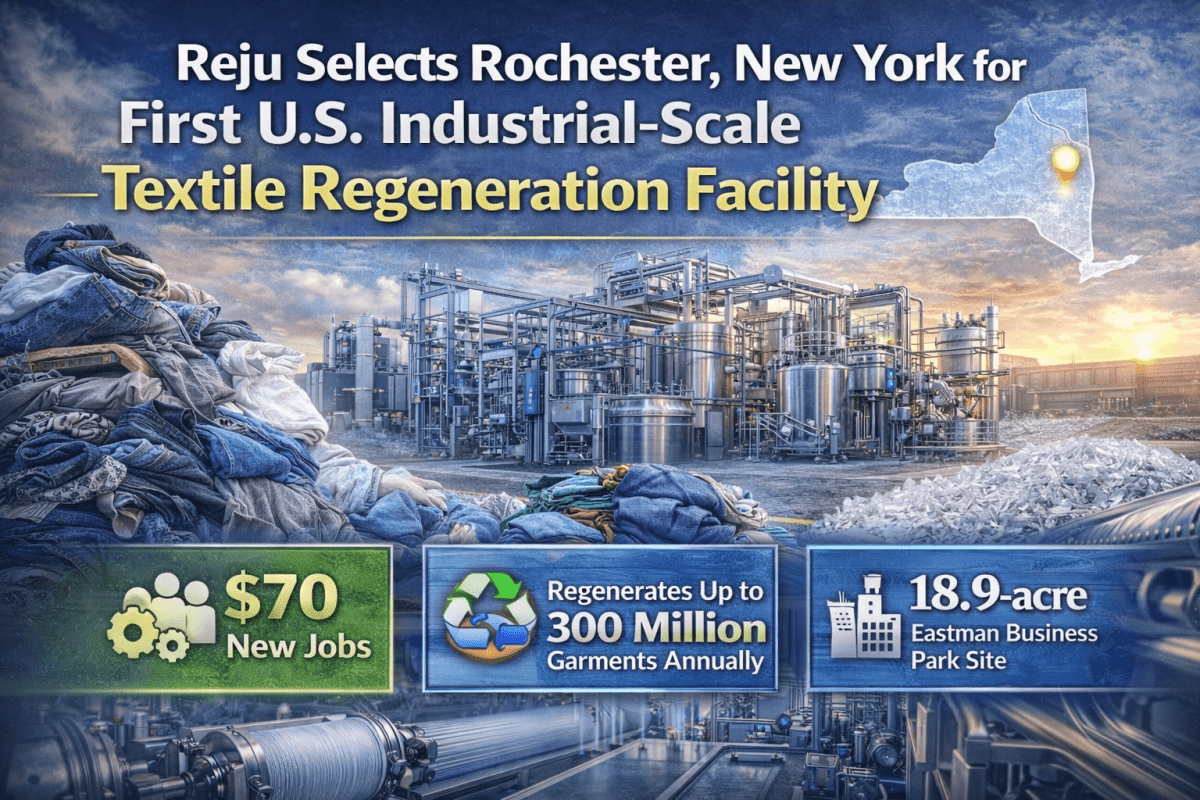

ROCHESTER, N.Y. (January, 20 2026) — Reju, a textile-to-textile regeneration company, has selected Rochester, New York, as the site for its first U.S.-based industrial-scale Regeneration Hub, marking a major milestone in the company’s global expansion and the advancement of circular textile manufacturing in North America.

The planned facility will be located on an 18.9-acre site at Eastman Business Park and is designed to regenerate the equivalent of up to 300 million articles of clothing annually that would otherwise be destined for landfills or incineration. The facility will produce recycled bis-hydroxyethyl terephthalate (rBHET), which will be repolymerized into Reju Polyester (Reju PET) for reuse in new textile products.

The project remains subject to a final investment decision by the board of Technip Energies, Reju’s parent company.

Building a Circular Textile Manufacturing Network

“As our first Regeneration Hub in the United States, this site selection represents a major step forward in building a truly global circular textile system,” said Patrik Frisk, CEO of Reju. “We are proud to bring sustainable manufacturing, innovation, and new jobs to the Rochester community.”

The Rochester facility will serve as a key node in Reju’s growing international network of regeneration hubs, complementing Regeneration Hub Zero, a demonstration facility currently operating in Frankfurt, Germany, and Regeneration Hub One, planned for the Chemelot Industrial Park in Sittard, Netherlands.

Reju’s proprietary recycling technology—developed in collaboration with IBM Research and Technip Energies—regenerates post-consumer polyester textiles into high-quality recycled polyester with a 50 percent lower carbon footprint than virgin polyester. The material is engineered to be recyclable multiple times, reducing the industry’s reliance on fossil-based raw materials.

Economic Development and Job Creation

The U.S. Regeneration Hub is expected to create approximately 70 new jobs and will support near-shoring and diversification of textile manufacturing supply chains in the United States.

“New York State is committed to creating good-paying jobs while supporting innovative projects that keep materials out of landfills and protect our planet,” said Kathy Hochul. “Reju’s investment at Eastman Business Park demonstrates how smart, forward-looking manufacturing can turn waste into opportunity and strengthen our green economy.”

Jim Moran, President of Eastman Business Park at Kodak, welcomed the project, citing the park’s infrastructure and legacy of advanced manufacturing as key assets supporting Reju’s circular production model.

Advancing Circular Manufacturing at Scale

Through partnerships with global brands, textile mills, and waste aggregators, Reju ensures full textile-to-textile traceability, converting discarded garments into raw materials for new products and advancing a scalable circular economy.

“The U.S. Regeneration Hub sends a clear signal that circularity at industrial scale is achievable,” Frisk added. “Post-consumer textile waste can become a resource—not a liability—and now is the time to accelerate that transformation.”

About Reju

Reju is a textile-to-textile materials regeneration company focused on recycling post-consumer polyester textiles and PET waste into high-quality regenerated materials. Owned by Technip Energies and leveraging technology developed with IBM Research, Reju is building a global circular textile system designed to reduce waste and carbon emissions. Learn more at reju.com.

About Technip Energies

Technip Energies is a global technology and engineering company with leadership positions in LNG, hydrogen, sustainable chemistry, decarbonization, and circularity. With more than 17,000 employees across 34 countries, the company helps turn innovation into scalable industrial solutions. Technip Energies generated €6.9 billion in revenue in 2024 and is listed on Euronext Paris.