To say that the global supply chain has seen more than its fair share of headache-inducing disruptions, bottlenecks, and infrastructural inefficiencies over the past several months would be an epic understatement.

Problems with suppliers; transportation disruptions; fluctuations in demand; new regulations or trade policies; technological failures; breakdowns in systems that manage inventory, orders, and logistics operations; labor shortages; and geopolitical tensions, such as the current tariff rollercoaster uncertainties, have impacted every link along the chain from raw material availability to shipping routes and schedules.

While some of the ‘big picture’ issues are beyond anyone’s direct control, navigating a course around the obstacles and maintaining a flexible supply chain to keep the goods moving no matter the circumstance requires strategic planning and serious investment in the latest distribution technologies and warehouse infrastructure.

Illinois-based mobile data technology developer Zebra Technologies recently released a study – Elevating Every Move: The Formula for High Performance Warehousing – that based on a nationwide survey of industry decision makers.

A full 70 percent of those surveyed “are under high pressure to modernize warehouse operations with 64 percent planning to increase funding over the next five years for warehouse modernization, and 87 percent agreeing that “without investing in technology to improve warehouse operations, their organizations will fail to meet business objectives,” adding that “these technologies help operators optimize workflows, improve accuracy and make smarter, real-time decisions.”

The warehouse landscape, the study concluded, “is evolving rapidly and standing still is not an option.”

The warehouse landscape, the study concluded, “is evolving rapidly and standing still is not an option.”

According to MarketsAndResearch.com, artificial intelligence “is revolutionizing warehousing by automating processes, optimizing inventory management, and improving operational efficiency. Traditionally, warehouses relied heavily on manual labor, leading to inefficiencies, errors, and slow processes.”

AI, the industry analyst said, “addresses these challenges by utilizing machine learning (ML), robotics, and advanced data analytics to streamline warehouse operations.”

AI-powered robotics, such as automated guided vehicles (AGVs) and drones, “are increasingly used for tasks like product retrieval, inventory checking, and order picking. These robots can navigate warehouses autonomously, improving speed and accuracy while reducing the need for human labor in hazardous or repetitive tasks.”

Artificial intelligence, it added, “also enhances inventory management by predicting stock levels, identifying trends in product demand, and providing real-time insights into inventory status. This capability ensures that warehouses operate at optimal capacity, reducing the chances of overstocking or stockouts.”

As customers expect faster delivery times, “warehouses must implement technologies that optimize operations and ensure swift processing of orders. AI offers the perfect solution by automating labor-intensive tasks and improving warehouse workflows.”

The growth in the implementation of AI in warehouse operations is being driven by several key factors that reflect the evolving needs of the logistics and supply chain industries, namely the increasing demand for fast and accurate order fulfillment, driven by the explosive growth of e-commerce.

Connecticut-based information technology research and advisory company Gartner, Inc. recently hosted a supply chain symposium in Barcelona, Spain.

According to the company’s senior researchers, “half of all supply chain software could be run by AI agents by the end of the decade” with AI “quickly shifting from a tool that supports decision-making to one that makes decisions on its own.”

Their presentation highlighted the increasing application of what it calls ‘agentic AI’ ─ a network of smart AI assistants that can handle supply chain tasks without constantly needing someone to guide them, place orders and buy materials, adjust inventory, respond to demand changes, and even suggest new business models.

Over time, these AI agents will get smarter, handle more complex jobs, and take more independent action based on the company’s needs.

“Supply chain technology investments need to improve efficiency or contribute to profit growth in today’s climate of uncertainty,” said Kaitlynn Sommers, senior director analyst at Gartner.

Agentic AI’ she said, “has the potential to do both by providing a new means to enhance resource efficiency, automate complex tasks, and introduce new business models across supply chains.”

In its latest industry study, Transport Logistic, found that more than half of logistics companies (58 percent) expect AI to become widely used and take over many tasks in logistics, such as route planning or avoiding empty runs, while 56 percent see the industry as a pioneer in digitalization—compared to only 32 percent in the economy as a whole.

“No human being is able to find the mathematical optimum from the multitude of time, route and resource combinations,” it stated. “Hence, AI’s main goal and added value is the self-learning supply chain.”

The advantage? “It prevents products from coming out of production when there are no trucks available for transportation, which would keep customers waiting and jeopardize the company’s goals. However, progress can only work without a silo mindset and rigid functional boundaries.”

Industry analyst McKinsey & Company has stated that AI-powered tools such as automation “can unlock 7 to 15 percent additional capacity in warehouse networks by identifying additional daily spare capacity, understanding variability in resource availability, and evaluating opportunities to improve efficiency.”

A major logistics provider “used a ‘digital twin’ powered by AI and machine learning to increase its warehouse capacity by nearly 10 percent without adding new real estate,” it said. “The system, an industry first, runs simulations to identify optimization levers specific to each warehouse in the network.”

Using a “highly granular approach,” the system evaluates the labor and assets such as forklifts and robots required to complete warehouse operations on an hour-by-hour basis and analyzes the impact of variability in demand and resource availability.

“This helps the company understand the true capacity of its facilities and improves decision making by accurately predicting the impact of changes in labor, assets, or material flows,” the company said.

The ‘elephant in the warehouse,’ so to speak, reshaping the logistics landscape is AI-driven automation, which continues to provide the momentum behind the re-forging of the critical warehouse/distribution link in the supply chain.

International supply chain manager GEODIS currently operates in 166 countries with more than 150 facilities in the U.S. alone, a number of facilities utilize automated systems designed by Massachusetts-based Locus Robotics.

The French company first partnered with Locus in 2018 and last December reached a milestone at its distribution facility in Carlisle, Pennsylvania, with the warehouse surpassing 10 million units picked.

The 575,000-square-foot center manages omnichannel consumer order fulfillment in the Midwest and eastern U.S. for a major global consumer electronics company.

“A lot of our business is in the e-com world, and we have to scale for the peaks and the valleys, especially during Black Friday, which is our peak season,” said Anthony Jordan, EVP and COO of GEODIS-Americas. “Locus has been very helpful in making us be successful in those types of operations, special operations that deal with retail, e-com type customers.”

According to Jordan, who oversees the implementation of new technologies at all the company’s U.S. facilities, the move to automate “didn’t happen overnight. It was a long road to get our people to adapt to it. It was a hurdle a while ago, but now I think it’s in our DNA.”

The move to automate meant refuting many of the fears surrounding the technology. “We’re not replacing people,” he said. “We’re just giving people new tools to do their jobs. Our objective was to bring in robotics to be more productive and get teammates to do their job better and make them more productive, which helped us drive down costs and helped us deliver better service to our clients.”

Addressing those fears has led to the creation of Embracing AI, a newly formed collaborative consortium of four technology companies with the stated goal of simplifying and accelerating operational AI adoption for companies of all sizes.

Backed by four technology developers ─ Tintri, Silicon Sky, Accure, and Pix Force ─ Embracing AI “is purpose-built to help companies turn their data into decision-ready insights while maintaining enterprise-grade security, reliability, and speed.”

Implementing AI “has become a strategic imperative, but many organizations struggle to unify the components required to make it work in production ─ infrastructure, automation, models, and expertise,” according to a statement announcing the formation of the collaboration.”

“As with any significant technology advancement, the majority of customers are interested in deploying advanced automation to improve operations, but lack the resources to connect the dots,” said Phil Trickovic, senior vice president at Santa Clara, California-based Tintri. “Clients all come to us with the same request – ‘make it simple.'”

According to Silicon Sky Solutions Specialist, Tim Averill, “AI doesn’t belong in a lab—it belongs in the hands of operators.”

While some companies equate embracing AI and automation with jumping into the deep end of the great technology pool, others, said analyst McKinsey & Company, “are taking an aggressive proactive slant at weaving the technology into their processes to determine where automation best suits the organization and focus on the capabilities that will drive value.”

For example, global retail mega-giant implements AI algorithms and robotics to streamline packing processes that sort packages more quickly and accurately. Robots powered by AI algorithms now handle much of the physical movement of goods at their fulfilment centers, determining the most efficient routes for sorting and packaging items.

For example, global retail mega-giant implements AI algorithms and robotics to streamline packing processes that sort packages more quickly and accurately. Robots powered by AI algorithms now handle much of the physical movement of goods at their fulfilment centers, determining the most efficient routes for sorting and packaging items.

These AI-powered machines can handle a range of tasks, from placing items into boxes to determining the optimal way to fit items to reduce space and packaging materials, reducing the time it takes to prepare packages for delivery and minimizing waste.

Amazon’s robotic system, for example, melds AI, robotics, and computer vision systems that allow computers to analyze and understand visual data to transport inventory, which reduces the time it takes to process an order through a fulfillment center by up to 25 percent, the company said.

Its packing algorithms assess orders, their destination, and required delivery times to consolidate orders within the same truck or trailer to reduce costs, optimize space utilization, and improve sustainability.

Another company taking an “aggressive proactive slant” on AI-driven automation to re-forge its operations is apparel industry leader Oxford Industries, Inc., which is building a new omnichannel distribution facility in Lyons, Georgia.

According to the company, which owns several apparel brands including Tommy Bahama, Lilly Pulitzer and Johnny Was, the new 560,000 square-foot distribution facility ─ due to open by the end of this year ─ will be fully automated and will be capable of handling more than 20 million units a year when fully operational.

Oxford Industries selected France-based Exotec to provide the automation system for the new facility that will feature more than 450,000 storage locations and more than 450 robots.

Exotec, the company said, “will integrate its hardware and software with third-party machinery to offer end-to-end warehouse automation and support receiving, decanting, sorting, and packing, as well as outbound shipment.”

The system, it added, “will also enable the company to effectively handle returns, significantly cutting the amount of time and labor needed to inspect, sort, and store returned items, streamlining the process of making it available for resale.”

Heavy equipment manufacturer Komatsu has partnered with Swisslog, a provider of warehouse automation and software, to install an “automation solution” system at its Ripley, Tennessee distribution center “to meet its growing omni-channel distribution needs.”

The system, which is comprised of 16,000 bins served by nine robots, is linked to a Swisslog software program, which provides warehouse execution, material flow and automation control system functionality in a single, modular platform and “can integrate seamlessly with existing warehouse management systems (WMS) to orchestrate the material flow,” said Komatsu.

The existing 685,000 square-foot distribution center serves as Komatsu’s primary hub for parts and equipment, containing production and replacement parts needed for Komatsu’s entire line of heavy construction equipment.

Eversana, a 3PL distribution company serving the life sciences industry, recently cut the ribbon at a new 358,000-square-foot, cGDP-certified distribution center adjacent to its current campus in Memphis, Tennessee. Locus Robotics system controlled by an AI-driven warehouse management system (WMS) designed by Florida-based Datex.

“The new WMS and the autonomous co-bots will increase warehouse accuracy and operational throughput,” the company said. “Both will be deployed across all Eversana 3PL facilities to improve processes, reduce manually intensive activities, and enhance accuracy and efficiency of the operation while improving employee engagement.”

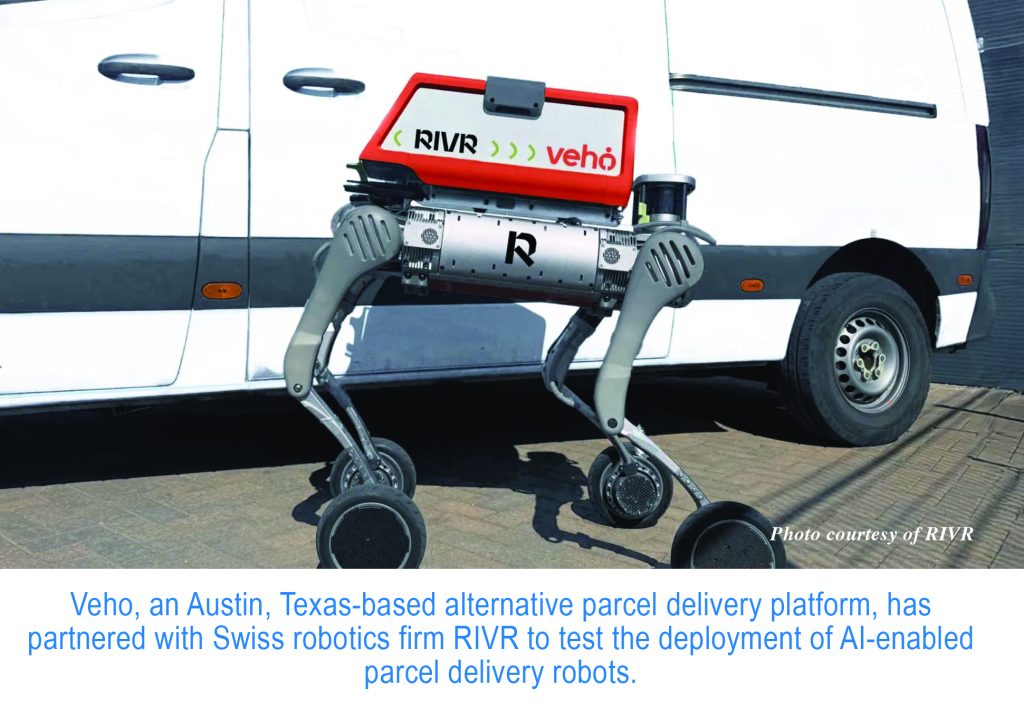

Taking the combination of robotics and AI distribution to the streets ─ literally ─ Veho, an Austin, Texas-based alternative parcel delivery platform, has partnered with Swiss robotics firm RIVR to test the deployment of AI-enabled parcel delivery robots.

The combination of the robots’ wheel-leg design and AI enables the robot to navigate real-world obstacles like stairs, gates, and uneven terrain—all the way to the consumer’s doorstep.

An initial test was conducted in Austin in late May with plans to expand to additional markets later this year based upon learnings during the initial trial.

“The robots are not intended to replace human delivery drivers,” said a spokesman for Veho. “Rather, they are intended to enable humans to deliver more parcels, faster, with less physical strain. The ability for humans to work with and manage robots performing deliveries may be particularly valuable in dense areas with many deliveries but limited parking.”

While a human driver completes one drop-off, “the wheeled-legged robot will deliver another, navigating from the delivery vehicle all the way to the customer’s doorstep, placing parcels according to customer’s instructions, while leveraging the Veho app to send a photo of each successful delivery.”

During the trial, “a RIVR employee accompanied the robot to ensure safety and delivery quality, while Veho and RIVR team members monitored the robot to learn how it performed during real life deliveries.”

The partnership “is an exciting next step in reinventing e-commerce delivery and enabling brands to turn shipping from a cost center to a value driver,” said Veho co-founder and CEO Itamar Zur.

“When it comes to delivery, customers care most about its reliability, speed and cost,” he said. “Working with RIVR will help us learn if pairing a human with a robot can improve delivery reliability, speed and costs, all while maintaining a great delivery and brand experience.”

“Unlike sidewalk robots, which are limited to curbside, attended deliveries with low throughput, RIVR’s robot operates in parallel with human drivers and at a speed that makes dense, multi-drop delivery commercially viable,” according to a statement from RIVR. “While drones offer reach in rural areas, RIVR is purpose-built for the complexity and scale of urban logistics—bringing automation to the final few meters of every delivery.”

“With the exponential rise in e-commerce, the last mile has become the most critical—and complex—link in the logistics chain,” said Marko Bjelonic, CEO of RIVR. “Our mission is to put one million delivery robots into the field, leveraging General Physical AI to scale urban robotics to where it’s needed most.”

Bio: Michael D. White is a published author with four non-fiction books and well more than 1,700 by-lined articles on international transportation and trade to his credit.

The warehouse landscape, the study concluded, “is evolving rapidly and standing still is not an option.”

The warehouse landscape, the study concluded, “is evolving rapidly and standing still is not an option.”